Synthetic Materials for Shoes

Synthetics in shoemaking refer to man-made materials that are often used as alternatives to natural materials like leather. These synthetic materials can offer a range of benefits, including durability, cost-effectiveness, and specific performance characteristics. Here's a deeper look into synthetics commonly used in shoemaking.

Polyurethane (PU)

PU is a versatile polymer used in various forms in shoemaking.

Key Qualities: It can be flexible or rigid, resistant to abrasion, and can mimic the appearance of natural leather.

Applications: Used for shoe soles, uppers, and as a coating for other materials to enhance durability. PU foam, specifically, is known for its lightweight and cushioning properties, making it ideal for footwear without adding unnecessary weight. It's often used in midsoles, insoles, and padding for enhanced comfort.

Considerations: While PU offers durability, it's essential to choose the right type for the intended shoe application. Over time, some PU foams may compress or lose their cushioning properties.

Ethylene-Vinyl Acetate (EVA)

EVA is a flexible and lightweight foam known for its cushioning properties. That's why we use this material in Dr Martens Boots Course to create thick but light shoe sole.

Key Qualities: It's lightweight, offers excellent cushioning, and is moldable.

Applications: Commonly used in the midsoles of athletic shoes, providing cushioning and rebound during physical activities. Also it uses to create outsoles for casual and ortopedic footwear due to its lightweight. It can also be integrated into the upper design of certain athletic and casual shoes like we do in Sneakers Making Course.

Considerations: EVA can degrade over time, especially when exposed to UV light, so it's essential to consider its longevity in outdoor footwear.

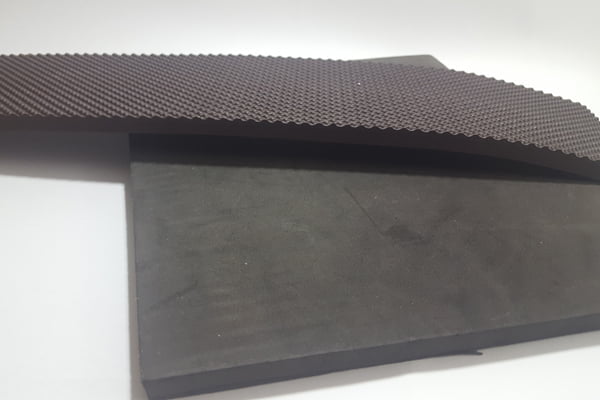

Thermoplastic Rubber (TPR)

A blend of plastic and rubber.

Uses: Often used in outsoles for casual and dress shoes.

Advantages: Combines the properties of rubber (like flexibility and durability) with the processing advantages of plastics.

Thermoplastic Polyurethane (TPU)

A class of polyurethane plastics with various properties.

Uses: Used in outsoles, midsoles, and sometimes as a protective overlay on uppers.

Advantages: Highly elastic, resistant to abrasion, and remains flexible at low temperatures.

PVC (Polyvinyl Chloride)

A widely-used plastic.

Uses: Can be used for outsoles and also in synthetic leather uppers.

Advantages: Durable, resistant to water and chemicals, and can be made in various colors.

In the world of shoemaking, synthetics offer a wide range of options for designers and manufacturers. They can be tailored to specific needs, whether it's the flexibility required for athletic performance or the aesthetic appeal of a fashion shoe. Additionally, as sustainability becomes a more significant concern, many of these synthetic materials are being developed to be more eco-friendly, either through recycled content or biodegradable formulations.

Online stores for syntetic materials in shoemaking

Here are some online stores where you can purchase various syntec materials for shoe making:

https://www.algeos.com/materials/foam-sheeting

https://www.alibaba.com/showroom/synthetic-leather-for-shoes.html

https://www.springfieldleather.com/shop-now/man-materials/plastics-synthetics?page=2