Complete Guide to How To Make Shoes

Want to learn how to make shoes?

My in-depth guide, crafted by an experienced shoemaker, covers all the fundamentals you need to get started.

How shoes are made

To understand how to make shoes you need to understand the basic process of how shoes are made.

Here's a concise breakdown of the shoe-making process: First, we design and apply a chosen shoe design onto the appropriate shoe last, creating an initial mock up. From this, we craft a foundational shoe template. This template helps us shape the patterns for both the shoe upper and lining. After cutting and sewing these patterns from leather, we assemble the complete shoe upper. This upper is then meticulously shaped around the shoe last, incorporating additional components. Following this, we affix the soles and heels, finalize with some finishing touches, insert the sockliner, and voilà, your shoe is born .

While this process generally has consistent steps, there are nuances based on several factors:

Shoe Construction: The method used in "making shoes" varies based on the construction type. Whether it's English welted shoes, Goodyear, cemented construction, moccasins, or stitched down construction, each demands a unique approach.

Materials: The materials you choose also determine the "shoe making process". Working with leather for the shoe uppers is different from using fabric. Similarly, shoe soles made from EVA foam, wood, or leather each have distinct processes.

Shoe Lasts: The shoe last (a mold in the shape of a foot) you select is crucial. Different shoes require different shoe lasts, like moccasin lasts or boot lasts. The shoe lasts' opening type can also influence the overall process of how to make a shoe.

Shoe Types: There are various shoe types, and while each type within a group may have a similar construction, there's a marked difference between the groups. For instance, hiking boots have soles molded onto the uppers. In contrast, orthopedic shoes are personalized to the wearer's needs. VANS sneakers, for example, come with specialized shoe lasts, while original Cowboy boots employ unique lasts, thicker leather materials, and a hand-stitched process.

So let's see the step-by-step process of how to make shoes, shoe making materials and tools to use, shoe patterns and shoe designs and how beginners in shoemaking can start making shoes.

Shoe making process Handcrafted vs. Machine-Made

Shoemaking process can be broadly categorized into two main sections: factory-made shoes and those crafted by individual shoemakers. While the fundamental steps in the shoe making process remain consistent across both methods, the primary distinctions lie in the facilities used, the time taken, and the capacity to produce shoes in bulk.

Factory-based shoe construction relies heavily on a team of specialized professionals utilizing advanced technology and machinery. The process is segmented into various departments, including design, pattern making, clicking (or cutting the leather), sewing and assembling, lasting, and finally, finishing and packaging. A significant advantage of factories is their ability to produce shoe parts, such as shoe insoles, stiffeners, and shoe soles, in advance. These are tailored for each shoe last type the factory works with, ensuring swift production. Consequently, factories can make shoes in large quantities within short time frames, catering to seasonal demands.

On the other hand, the shoemaking process by individual shoemakers is meticulous and time-consuming. A shoemaker typically handles every step, from creating shoe patterns and cutting leather pieces to assembling and sewing them. They also prepare shoe insoles, stiffeners, and soles, often crafting heels by hand. While some may use machinery, like sanding or skiving machines, the essence of their craft remains handmade. This approach is highly personalized, as they make custom shoes tailored to individual preferences. However, this level of customization restricts the number of shoes a shoemaker can produce.

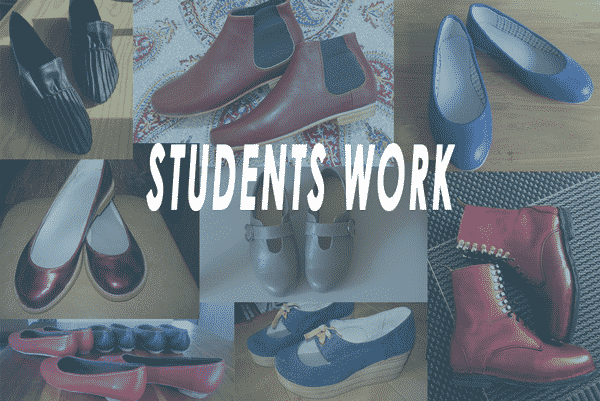

For those wondering how to make shoes, how to make your own shoes, it's worth noting that every beginner can try their hand at shoe construction and that is partially what you can expect from our Online Shoemaking Courses.

For someone who wants to learn how to make shoes from most basic footwear constructions , we have tailored shoemaking courses and shoe making programs that will teach you how to make shoe step by step with a minimum set of shoe making tools and our dedicated support.

If you already have experience with making shoes we have a more advanced shoe making course that will upgrade your skills to the next level.

If you're interested in understanding how shoes are crafted, here's another excellent resource for you.

Make shoes step by step for beginners

Here is a pro approach for beginners to make shoes step by step at home. We offer comprehensive shoe making courses that teach the full process of making shoes. Starting from shoe design and shoe pattern making, we guide you until you have a finished pair of shoes. Our approach allows aspiring shoemakers to work with simple shoe making tools and materials, making it possible to create a shoe or even make your own shoes from the comfort of your home. The First thing you should know is where to start (“How to make shoes – 100 % guarantee! [Where to start?!]”).

Shoe design is actually a first step in the shoe making process and if you want to learn how to make shoes this is the first thing you need to learn

Shoe design

A shoe design is the initial phase in the shoe-making process, as has been mentioned. For those who aspire to make their own shoes, understanding the intricacies of shoe design is paramount. As every budding shoe designer knows, the initial design sets the tone for the final product. So, if you're keen on learning how to make shoes or want to make your own shoe, understanding shoe design is crucial when diving into the world of footwear creation

One essential aspect to grasp is that shoe design is intrinsically linked with shoe pattern making. Every line you sketch, whether you're drawing shoes or conceptualizing sneakers drawing, will influence the subsequent shoe pattern. Sometimes, what seems feasible in a shoe drawing might pose challenges during the pattern-making phase. Therefore, how to draw shoes and the process of pattern creation are two intertwined steps that dictate the final outcome of your shoe designs. Therefore I created a unique Footwear Design Course where I teach how to design shoes through shoe pattern making.

Also,for those eager to delve deeper into the art of shoe creator techniques, I've curated a list of valuable resources to further enhance your knowledge about shoe design.

This post is about a shoe design course that encompasses mastering various footwear types, understanding construction rules, simplifying the design process, and creating diverse shoe collections with limited resources. Notably, drawing skills aren't a prerequisite; the course emphasizes a hands-on, Freehand pattern technique. Dive into this transformative course to elevate any shoe-making journey

This guide delves into the art of choosing the perfect footwear based on leg shape. It categorizes legs into four types: Ideal, O-shape, Keyhole, and X-shape, offering tailored shoe design recommendations for each. The right shoe can accentuate the beauty of one's legs, hiding imperfections and emphasizing strengths. Whether buying, making, or selling shoes, understanding these nuances ensures satisfaction and boosts sales. The post emphasizes the importance of recognizing one's unique leg type and choosing footwear that complements it.

Creating a cohesive footwear collection requires a unifying theme, often achieved by repeating design elements across models. While simply copying and pasting elements is discouraged, a creative approach offers versatility. Techniques include integrating the design element within the shoe pattern, emphasizing specific details, using color differentiation, and experimenting with material combinations. This method streamlines the design process, enhances focus on the core idea, and maximizes creative potential

Footwear designers, like Chie Mihara, offer unique insights into shoe design. While some use traditional shoe drawing methods, Mihara experiments with magazine images and leather placements for inspiration. Embracing diverse approaches, from drawing shoes to hands-on experimentation, can lead to innovative shoe designs and aid budding shoe creators

Shoe designers often prioritize shoemaking skills over drawing shoes. While shoe drawing is valuable, understanding the technicalities of shoe design and production is crucial. This knowledge aids in creating practical and innovative shoe designs. Whether aiming to be a professional shoe creator or pursuing it as a hobby, mastering shoemaking techniques enhances the design process

Shoe design is more than just sketches; it's the foundation of the shoe-making process. Many aspiring shoemakers struggle with the technicalities of designing shoes, often due to a lack of knowledge. This post introduces the Freehand Pattern Technique, a unique approach to shoe design without the need for sketching or expensive software. It emphasizes understanding shoe construction, how shoes are made, and how to skive and manipulate materials. The technique offers a hands-on approach to making shoes, allowing designers to visualize and adjust designs in real-time.

Shoe last

In the realm of shoemaking, the shoe last is very important. Directly linked to shoe design, it's essential to understand its role in the shoe making process. Each shoe type, be it sandals or boots, requires a specific shoe last. For instance, a sandal design won't align with boot or pump shoe lasts; it demands a specialized last. So, if you're venturing into making various shoe types, do you need distinct lasts for each? Not always. For beginners, there are resources highlighting the best shoe lasts to start with (Perfect Shoe Last To Learn Shoemaking [1 Shoe Last = 10 Shoe Types]).

Dive into the world of shoemaking, understand shoe construction, and embark on crafting your very own shoes.

Shoe Pattern and Templates

After designing your shoe and choosing the right shoe last, the next step is creating a shoe pattern, the heart of shoemaking. This pattern is vital for the comfort and aesthetics of the footwear. Understanding the shoe making process is very important for those eager to learn how shoes are made. The process starts with a basic shoe pattern, followed by developing the upper and lining patterns. Different shoe types have varied pattern constructions, but the steps remain consistent. This journey also includes making patterns for inner parts like stiffeners.

Here are some resources to provide a deeper understanding of shoe pattern construction:

For a complete giude about process of shoe pattern making and full list of articles covering various steps of shoe pattern making, please visit my Shoe Pattern Directory

Upper and lining leather cutting

After completing the full shoe construction pattern, the next step in the shoe making process is to cut the leather using the upper and lining patterns you've developed. If you're curious about how shoes are made, this step is essential. Simply place your cardboard templates on the leather surface and cut them out using a basic utility knife. In professional shoe construction terms, this process is known as "clicking" and typically involves a special clicking knife. However, as highlighted, we're focusing on using simple tools that are easily available. For those looking to make a shoe or learn more about how to make your own shoes, this is a valuable resource where you can learn how to cut leather with straightforward tools.

Shoemaking involves crucial steps, including cutting shoe leather. Two methods exist: "Copy and then cut" (CC) using scissors after marking with a silver pen, and "Cut right away" (CRA) using a knife directly on patterns. CRA offers precision and professionalism in shoemaking.

Assembling and sewing of upper and lining parts

In the shoe making process, assembling and sewing the upper and lining parts is a key stage in how shoes are made. While each shoe type has its specific order, the general approach for shoemakers begins with assembling all leather components, including tasks like how to skive and how to fold. Once this is done, it's important to combine the sewn upper with the sewn lining and stitch them together. For those looking to make their own shoe, understanding this shoe construction step is very important and here are few tutorials where you can learn step of making shoes:

If you would like to learn on how to make leather straps for you sandals, here is great shoe making tutorial about it:

Lasting of the shoe upper

In the shoe making process, this is the stage where your shoe design comes to life in real leather. It's where the sewn shoe upper is placed on the shoe last, edges are pulled using specialized shoemaking pincers, and then attached to the insole using shoe adhesive. This construction phase includes creating an insole and preparing stiffeners before the actual lasting. While there are various methods shoemakers employ in lasting, a common approach is to first position the back part (including counters) of the upper correctly, then set the front part, including the toe puff. Properly sealing the edges to the insole is key. For those wanting to learn more about this step, here are few tutorials devoted to lasting process:

If you want to make a leather insoles for sandals, here is great shoe making tutorial:

Shoe sole construction

Shoe making is a detailed craft, with the shoe sole construction being a key step in the shoe making process. The design and construction of the sole depend on various factors: the materials you choose, the type of construction technique, and the tools available, especially if you're aiming to make your own shoe at home.

There are several widely used shoe sole constructions. These include cemented sole, welted sole, stitch-down sole, and opanka sole constructions. Depending on the construction method, you'll need a shoe sole pattern. Once you have this pattern, you'll cut out the chosen material and either attach or sew it to the shoe bottom. Materials also play a significant role. For instance, if you choose vegetable-tanned leather, the possibilities for how shoes are made expand greatly. Such a material allows for a variety of finishing touches and designs. For enthusiasts looking to understand more about how to make your own shoes, there are numerous shoemaking tutorials that explain different shoe sole constructions.

Whether you wish to make a shoe from scratch or understand the process, these resources are beneficial.

Making heels

When it comes to the shoe making process, a significant step involves heel attachment. You have two choices: either attach ready-made heels or learn to craft your own. Within my shoe-making courses, I offer detailed courses on how to make your own shoes, focusing on heel construction. Discover diverse shoe construction techniques using varied materials, including vegetable-tanned leather, wood, EVA, and cork. Before starting this process, whether you opt for pre-made heels or design your own, it's important to measure the heel height of your shoe accurately.

Explore the intricacies of how shoes are made with my courses that teach the heel-making process using different materials:

Price: €167

14 Lessons

Length: 16 Hours

Price: €207

15 Lessons

Length: 16 Hours

Price: €237

31 Lessons

Length: 33 Hours

Price: €207

26 Lessons

Length: 26 Hours

Price: €457

19 Lessons

Length: 21 Hours

Finishing of making shoes

In the shoe making process, the final step is removing your crafted pair from the shoe lasts. First, it's important to clean any dust, marks, and glue. Some might choose to enhance their design with wax or patina applications. Next, the process delves into creating a sock liner - an essential aspect of shoe construction. This involves pattern making for the sockliner, an inner component that overlays the shoe insole. Sockliners can be varied: from padded versions to uniquely designed ones that elevate the overall look of the shoes. Mastery in how to make shoes begins with understanding the basic pattern for sockliners, which can then be adapted for various designs.

Here's a reputable resource on the creation of sockliners:

Best free shoe making tips and tutorials for beginners

While we've highlighted the primary steps in the shoe making process, it's very important to understand that each stage includes many shoe making techniques and steps. For those passionate about making shoes and eager to master the craft, our online shoemaking courses offer detailed insights on how to make your own shoes.

Whether you're a novice shoemaker or just curious about how shoes are made, this curated list of our best shoemaking tips and tutorials can be invaluable:

Shoe making tools

While the world of shoe construction offers a wide array of professional tools, from specialized knives to hammers, beginners need not feel overwhelmed. Instead, starting with a basic set of shoemaking tools can be beneficial. Learning how to make shoes isn't merely about having advanced tools; it's mastering the shoe making process and techniques. Once you grasp the core methods of making shoes, even the simplest tools can enable you to make your own shoe with professional finesse and this is a good source (“Beginners in Shoemaking Tools and Materials Definitive Guide 2023”) where you can learn about most of this tools and how to work with them and here is another smart approach on how to make shoes with minimum shoe making tools.

For those eager to explore the world of shoemakers, here's a detailed list of shoemakers tools important for your craft and a list of source where you can buy shoemaking tools.

Shoe making materials

Selecting the right materials for shoemaking is a significant consideration in the shoe making process. A wide variety of materials are available, ranging from diverse types of shoe leather and fabrics for the shoe upper and lining, to eco-friendly or natural substances for shoe insoles and soles. You can even use EVA material or plastic for heels. Each material brings its unique benefits and limitations. The choices you make will largely be influenced by your shoe construction, design, the specific type of shoe you're aiming to make, and your personal preferences.

Here, you can discover a detailed resource on the primary materials and a full list of different leather types used in shoemaking.

Custom-made shoes

Custom-made shoes or bespoke shoes represent the zenith of shoemaking, offering a unique blend of luxury, fit, and personalization. Unlike standard shoes, which often use a one-size-fits-all approach, custom-made shoes are tailored specifically to an individual's feet. This is achieved through the meticulous customization of the shoe last, which is the foundation of any perfect pair. Based on precise foot measurements, this last ensures an unparalleled fit. Central to the allure of custom-made shoes is the use of natural materials. Vegetable-tanned leather, in particular, is revered for its adaptability, durability, and organic origin. Key components, such as insoles and stiffeners, benefit from this material's ability to mold when damp and solidify upon drying, yet retain flexibility. But the true essence of custom-made shoes lies in their promise of a matchless fit. Mass-produced shoes often overlook the subtle intricacies of individual feet, leading to discomfort or improper support. Custom shoes, however, cater to these nuances, whether it's wider feet, unique arch support, or other specific requirements. In a world dominated by mass production, custom shoes stand out, offering both comfort and a touch of personal luxury. For those eager to learn more about the craft or simply enjoy wearing them, understanding the value of custom-made footwear is vital. Within our online shoemaking courses, we offer two specialized shoe courses dedicated to this craft:

This is the “Bespoke Derby Hand-sewn Opanka Shoe Making Course” and

“English Welted Brogue Oxford Men's Shoe Course”

Also, here you can find extra sources about custom-made shoes:

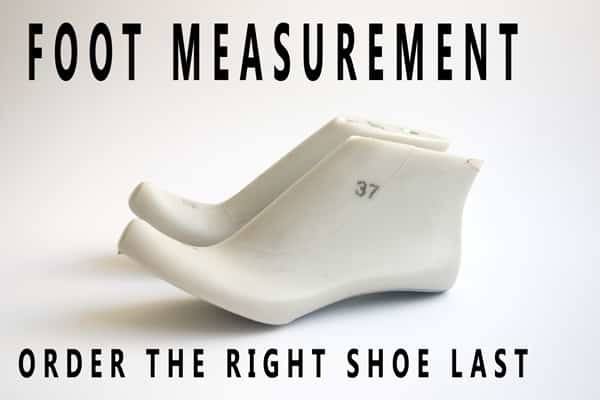

Sizing and fit

Shoemaking is more than just a craft; it's an art that starts with understanding your feet. Most of us are wearing the wrong shoe size, not realizing that the right fit is integral to the shoe making process. One of the first steps in learning how to make your own shoes is to chose the right shoe last size. Grasping the importance of the shoe last - a copy of the human foot, is very important in the shoe construction journey. To make shoes that fit seamlessly, you need a precise foot measurement. Whether you're new to making shoes or a seasoned shoemaker, you'll be amazed to discover your true shoe size. Every foot has a unique length and width. For instance, a size 38 shoe can have varying widths. Professional shoemakers and last makers dedicate years mastering these measurements, especially in bespoke shoe making.So if you want to start making shoes with the right shoe last size, make sure to learn on how to measure your feet using this simple shoe making approach:

Shoe Types

In discussions about shoe design, the topic often touches upon various types of shoes. In reality, there are several primary classic shoe types. Most contemporary shoe styles are derivatives of these classic designs. Understanding the construction of these classic shoe types allows one to innovate and craft unique shoe designs.

Below, I've highlighted the main classic types of shoes along with their defining features:

Flat Ballet Shoes: These are closed women’s court shoes where the neckline sits below the instep. The heel height is up to 4 cm.

Pump Shoes: Another closed women’s court shoe, this style has a heel height that starts from 4 cm and goes higher.

Mary-Jane Flats/Pumps: These shoes resemble flats or pumps but feature a strap that can either encircle the ankle or sit above the instep.

D'Orsay Flats/Pumps: it’s half -closed women court shoe type. The design is characterized by separate front and back parts of the upper, which elegantly highlight the middle of the foot.

T-Strap Ballet Flats/T-Strap Pumps: These women's court shoes have a neckline similar to classic ballet flats or pumps. They come with two perpendicular straps, one lying in the middle and the other intersecting it. This style usually has fastenings like buckles.

Slingback Pumps/Flats: This design is similar to classic flats or pumps. However, they have a heel opening shaped like a strap that can include fastenings such as buckles, Velcro, or an elastic band.

Loafers: These are closed unisex court shoes with a topline higher than the instep. The design primarily comprises two parts: the vamp (usually with a leather strap) and the sides and toes.

Moccasins: These resemble loafers but differ in construction. The upper overlaps the shoe's bottom, and the vamp is hand-sewn to the primary upper part.

Oxford Shoes: A closed unisex court shoe, the quarter part contains laces and is firmly sewn to the vamp.

Derby Shoes: Similar to Oxfords, the quarter part has laces but is partially sewn to the vamp, allowing for an opening.

Sandals: These unisex shoes come in diverse styles, primarily consisting of straps. The foot is visible through the straps.

Mule Sandals: A unisex sandal characterized by a single wide front strap.

Slippers: These shoes have a broad opening for easy wear and are typically used indoors.

Boots: Covering the entire foot and leg, boots can reach above the knee. They come with various openings like zippers or laces.

Ankle Boots: Similar to boots but only reach the ankle.

Cowboy Boots: Historically worn by cowboys, these boots reach mid-calf and lack fastenings.

Sneakers: Unisex sport shoes, similar to Oxfords or Derbies, that can vary in height and style. They can be specialized for specific sports or casual wear.

All these shoe types can be crafted from diverse materials and can vary in sole construction. There is also a specialized footwear that may share design features mentioned here but have unique characteristics.

Specialized Footwear

Specialized footwear encompasses a wide range of shoe types designed to serve specific purposes. From orthopedic shoes that prioritize comfort and support, to dance shoes engineered for flexibility and elegance, and sports shoes engineered for performance and durability – each category demands distinct techniques and considerations. Delving into specialized footwear allows you to create functional and comfortable shoes tailored to individual preferences and requirements.

Creating specialized footwear begins with a solid foundation in traditional shoemaking techniques. You'll need to understand the intricacies of materials, patterns, and construction methods that align with the intended use of the shoes. While crafting orthopedic shoes might involve ergonomic design principles and cushioning materials, creating dance shoes could focus on flexibility and aesthetics. Researching the specific needs of each footwear type is crucial for delivering both comfort and functionality.

Kids' Shoe Making

When diving into the world of shoe making, it's important to recognize that crafting footwear for children isn’t just a smaller-scale version of adult shoe production. While many of the shoe types are consistent across both categories, the methods and specifics for creating kids' shoes present distinct variations.

One of the most significant differences in making children's shoes lies in the design of the shoe last. The lasts used for kids' footwear are typically crafted to accommodate the unique shape and volume of a child’s foot, which often has a chubbier profile compared to adults. This special configuration ensures that the shoes fit comfortably while accounting for the rapid growth children experience. Moreover, prioritizing the use of natural, breathable materials is of paramount importance when crafting footwear for the younger demographic.

Children’s feet tend to sweat more, and using breathable materials ensures their feet remain dry and comfortable.

Another key aspect to consider in kids' footwear design is the balance between support and flexibility. The heel section of the shoe should be reinforced to provide the necessary stability, ensuring that the child's foot remains securely positioned. At the same time, it’s vital that the shoe remains soft and flexible, allowing for the natural movement of a child's foot and aiding in their walking development. In essence, producing kids' shoes requires a unique blend of expertise and attention to detail, focusing not just on style but also on the health and comfort of the young wearer.

Shoe parts

To fully grasp your design possibilities when making shoes, it's very important to familiarize yourself with all the different parts of a shoe. While some shoe parts are common across various types of footwear, there are specific parts that are unique to certain shoe types. By learning about how shoes are made, you empower yourself to innovate and create. So, if you've ever wondered about how to make your own shoes or simply wanted to understand the intricacies of shoe construction, begin with the fundamentals: know each and every part of a shoe.

Budget-Friendly Options to Learn Shoe Making

Starting out in shoe making? It's important to know that beginning this craft doesn't always demand a large financial commitment. There are cost-effective options and strategies designed for those new to the shoe making process.

One key piece of advice for newcomers is not to acquire every tool available in the shoemakers' arsenal all at once. Instead, adopt the mindset "slow and steady wins the race." Begin with basic and simple shoemaking tools. As you advance and expand your knowledge about how to make shoes, you'll naturally discern which additional tools may benefit you.

Often, you might discover that the basic tools are more than enough, especially if your aim is to make your own shoe. If you're seeking a place to find these beginner-friendly tools, there are resources available, like the one mentioned here, which offers a curated list of budget-friendly tools and materials perfect for those starting in shoe construction.

Additionally, there are innovative alternatives that can stand in for some of the more expensive, industrial-grade equipment. For instance, instead of splurging on a high-priced sanding machine, a tool like a Dremel drill can serve the purpose, as highlighted in my shoemaking courses. And, if securing a sewing machine feels overwhelming initially, don't be discouraged.

With a genuine passion for the craft of making shoes, hand-sewing is a feasible option, as many of my students can attest.

Whether you're considering shoemaking classes or are exploring shoe making courses online, remember: every expert was once a beginner. Equip yourself thoughtfully, and you'll be on your path to understanding the intricacies of how shoes are made.

Here are resources mentioned in this topic:

Time Commitment to make shoes by hand at home

A common question beginners in shoemaking often ask is: how long does it take to craft a shoe by hand? There's a misconception that the process of making shoes might span several months. However, based on my extensive experience with shoemakers from various backgrounds and countries, the time taken is considerably less than most anticipate

Here's a general breakdown of the shoemaking process:

Day 1-2: Create a shoe pattern.

Day 3-4: Cut leather, assemble, and sew the shoe upper.

Day 5: Prepare for shoe lasting by crafting the shoe insoles.

Day 6: Last your shoes.

Day 7-8: Construct the shoe sole and, if you're using ready-made heels, attach them. Crafting heels by hand will require an additional 2 days.

Day 9: Complete the shoe finishing.

In total, if you dedicate around 3 hours daily to the craft, you can make your own shoe in roughly 11 days. For those eager to learn how shoes are made, understanding the sequence of the shoe construction process is very important. As a shoe creator, start with simpler shoe types and gradually progress to more intricate designs for an efficient learning experience.

Common Mistakes in the Shoemaking Process

As you embark on your journey into the realm of shoemaking, be mindful of potential pitfalls. Here are some typical mistakes:

1.Lack of Preparation: Before you even begin to make shoes, understand the entire shoe making process. This will ensure you're not missing any crucial steps in shoe construction.

2.Choosing the Wrong Materials: Not all materials are suitable for every shoe type. Research is crucial when determining which materials are best for your shoe creation. For those struggling with subpar supplies, check out this insightful article on enhancing your craft despite having less-than-ideal materials.

3. Improper Measurement and Last Selection: Accurate measurements are fundamental when setting out to make shoes. Before embarking on any shoemaking project, ensure you possess the correct shoe last size. Based on your feet's measurements, there might be a need to customize a standard shoe last according to specific parameters. Even slight deviations can significantly impact the comfort of the finished shoe. Always double-check and, if necessary, adjust to ensure a perfect fit.

4. Don't Rush the Process: Start with simple shoe constructions, like flat ballet shoes or loafers. Then, progress step by step to more advanced footwear types, acquiring confidence and experience steadily.

5. Overlooking the Finishing: A shoe creator knows the importance of finishing touches. Ensure edges are smooth and the final product is polished to perfection.

6. Skipping Prototypes: Crafting a prototype is a crucial step in the shoemaking process, especially for beginners. Creating a mockup will allow you to revisit and refine your shoe pattern — a phase where many novices tend to err. Furthermore, producing a prototype equips you with invaluable hands-on experience. This "trial run" not only helps pinpoint potential mistakes but also gives you the confidence and know-how to ensure a smoother process when crafting the final shoe. Consider it a rehearsal that sets the stage for a flawless performance in making your desired footwear.

For an in-depth look at common mistakes, consider reading our article on the "8 common mistakes that beginners do" in the realm of shoemaking. Remember, while the journey of learning how to make a shoe is thrilling, it's equally important to be aware of these common missteps. By being mindful, you can ensure your path in making shoes is smooth and rewarding.

Here you can find all valuable resources on how to sidestep common mistakes in your shoemaking journey:

Building Confidence

Diving into how to make shoes can be daunting for beginners. However, every expert was once a novice. Marcia Brown's story exemplifies this. Starting with zero knowledge in shoemaking, she transitioned from wanting to make her own shoes to launching "Marcia Brown Footwear".

A staggering 95% of our online course students begin without any experience in shoe construction. Whether they aim to make shoes for personal comfort or establish their brand, our courses guide them step by step through the shoe-making process. Marcia’s first creations, ballet shoes, showed her potential and passion. With each pair, she honed her skills, moving from the basics of how to make a shoe to mastering advanced designs.

Her journey underscores the transformative power of dedication and learning. If you've ever pondered the intricacies of how shoes are made or wished to delve into the shoe construction process, let Marcia's journey inspire you. In the vast world of shoemakers, with determination, your success story awaits.

Business or Entrepreneurship in Shoe making

Starting to create a shoe brand doesn't always require a vast budget. Instead, forward-thinking entrepreneurs are discovering intelligent ways to make a mark in the footwear industry. One key strategy is the hands-on approach to making shoes and prototypes. Instead of investing heavily in the prototyping phase, which can be a significant outlay, budding shoemakers can learn how to make their own shoes. This hands-on method not only gives a clear understanding of shoe construction but also ensures that the product aligns with the brand's vision.

Moreover, while major brands diversify their collections using numerous shoe last types and corresponding components, such as insoles, soles, and heels, there's an alternative for budget-conscious entrepreneurs. By mastering the shoe making process with just one shoe last type, you can design a variety of shoe designs. This strategic approach allows for the development of an entire shoe collection, where you make your own shoe prototypes.

So, by understanding how shoes are made and being your own shoe creator, you can smoothly move from design to launch, taking those key steps to establishing your brand in the market.

Explore these insightful articles to guide you in launching your own brand:

![10-Shoe-types-with-ONE-SHOE-LAST-[Smart-Shoemaking-] 10-Shoe-types-with-ONE-SHOE-LAST-[Smart-Shoemaking-]](https://www.shoemakingcoursesonline.com/wp-content/uploads/2018/12/10-Shoe-types-with-ONE-SHOE-LAST-Smart-Shoemaking-.jpg)