Shoemaking is an amazing craft that can allow you to make your own shoes with any shape, any design!

You can make a comfortable and at the same time beautiful footwear that will set you apart from the crowd.

Making shoes that you love will emphasize your personality. If you're keen to delve deeper into the art of shoemaking, don't miss this article: "How to Make Shoes".

To have this possibilities, you must gain this shoemaking knowledge, and I am here to help you do that.

I already wrote few post about the shoe lasts but this theme is endless.

There are so many details about shoe last that you should know, that it will never be enough.

If you are a beginner in shoemaking and just getting started to source materials and tools, you can understand very quickly that it is pretty hard task, to find appropriate shoe lats.

If you purchased some old shoe last but you don’t like the shape, it is too narrow or too wide for you feet, don’t worry, you can fix it.

So in this post I will show you a few shoemaking techniques on how you can change the shape of your shoe last, and for more free shoemaking tutorials, you are wellcome to read this article: "How to make shoes-Best Free Shoe Making Tips And Tutorials For Beginners".

Make sure to read till the end and watch my video tutorials as well (there are 2 excellent tutorials)

Customize your shoe last

To make comfortable shoes you need to customize your shoe last according to your feet measurements.

It is especially super important, if you don’t have standard feet, meaning they are too wide or too narrow. To understand more about shoe size fitting and the benefits of custom-made shoes, explore these links.

What should you do if your shoe last has standard parameters?

You need to do to customize it!

Here is how it’s done:

1. Take a measurements of your feet:

The outline, the line of the feet bottom, the girth of the joints, the waist, the instep,the short heel girth and long heel girth.

2. Take the same measurements of your shoe last

3. Compare the measurements of you feet and the measurements of your shoe last to understand where you need to change your shoe last

4. Change the shoe last.

Work with vegetable tanned leather, if you need to enlarge your shoe last.

Work with rasp, if you need to reduce it.

5. When working on your last don’t forget to measure it each time to fix it correctly.

Note: if you want to know how what is the proper shoe last size for your feet, make sure to read this post "How to Measure Your Feet Size[ Order the right shoe last]" where I give short tips on how to measure the main parameters of your feet.

How to make your shoe last shorter

Using this shoemaking approach you can make your shoe last shorter, if the toe shape is too long.

1. Measure the length of your feet

2. Measure the length of your shoe last

3. Compare these 2 measurements to know on how much you can reduce the toe shape of the shoe last.

4. Make a pattern of the last bottom (insole pattern) and mark on it a line that will be the new edge of your shoe last.

5. Reduce the toe shape working with rasp or a sandpaper.

How to make your shoe last shorter in the back part

Why would you need to shorten your shoe last in the back part, in the heel?

The fact is that when we shorten our shoe last in the front part, the shape of the toe changes a little bit because we reduce the volume of the toe. And if you want to keep your toe shape untouched because you really like the shape as it is but you have too long shoe last that must be shortened, you can reduce it in the back part.

This process is more complicated than the previous one because the shape of the heel has a lot of curves that must be kept as they are during the process of shortening. It is like you will squeeze your shoe last in the middle, so the original shape of the heel remains the same.

Preserving the original back shape of your shoe last is very important.

Why would we have to preserve the original shape while reducing the shoe last?

The back shape of the shoe last is constructed according to the anatomy of the feet. It has certain curves, parameters and if you change them in some places you will get uncomfortable shoes unless you want to change them for the purpose of following some parameters of your feet.

In my Bespoke course, I teach how to customize a standard shoe last according to the feet measurements where you can learn how to change your shoe last in any place you need following your feet configurations.

You can learn more about the process of customization in this post “How to Make Bespoke Shoes From Home [with me]”.

Because of these “unwanted” modifications you can get a wider back part, or narrower than it needed to be, or with the too straight shape of the back curve. This is how you can get incorrect shape in the back part.

How to avoid mistakes in shortening shoe last

You probably will have these mistakes if you will change your shoe last in the back part by eyes.

There is a shoemaking approach on how to preserve the original shape during shortening the heel part.

Following this approach that I will show you in the minute, just keep reading, will help you :

-To keep the original anatomical shape of the shoe last back

-To avoid mistakes during work that can lead to the creation of the wrong heel shape and as a result, you will make uncomfortable shoes working with this shoe lasts

-To make both halves of your shoe lasts identically

All these benefits I described here briefly but their importance is enormous if you want to make comfortable shoes.

The shoemaking approach to shorten the back part of the shoe lasts correctly

To shorten your shoe last from the back part by keeping the original shape you need to have some reference to the original heel shape. Using this reference, a kind of blueprint of the original last shape, you will be able to control yourself during the work following the original shape.

There are probably few references to the heel shape. They are the profiles, the copy of the heel shape: the horizontal shapes, vertical shapes of the back part and shapes of the sides.

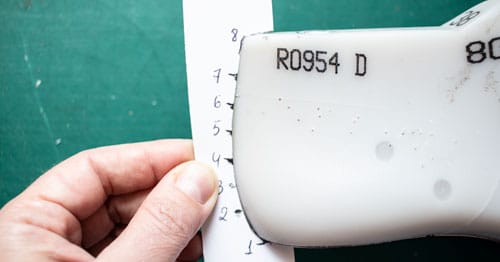

To create these profiles very easily and fast you need to have some ruler (not a shoemaking one). It is called gauge contour and you can buy it in your local hardware store or on amazon.

It has steel pins that move when you push the gauge contour by placing it to some surface that you want to take a copy of. Working with this instrument we will take different copies of the heel last shape and transfer them to the cardboard to have a pattern, a contour of each needed heel shape. To know more about shoe patterns in making shoes, you are wellcome to read this article: "How to make shoes-Shoe pattern and templetes".

In total you will have a vertical profile, few horizontal profiles of the back shoe last part and few side profiles.

Now, find this gauge contour, prepare the cardboard and utility knife, some markers, and your patients because the process of making the last profiles can take some time.

How to make the shoe last shorter working with profiles

1. Create a vertical control profile of the back curve of the shoe last

First mark with a marker the center backline. Place the gauge contour along this central line and push on it to copy the outline of the horizontal back curve. Then transfer this shape from the gauge to the cardboard.

2. Divide the vertical control profile into a few equal segments.

Along with the central line mark points in the distance of 1 cm from the bottom edge till the top edge. Transfer these points to the vertical profile and number them. The first point is the bottom edge (the outline of the insole) and the last one is the top edge.

3. Make horizontal profiles of the back shape

Place the gauge contour to each mark on the central line of the shoe last in the way where the walls of the gauge are parallel to the bottom edge of the shoe last. Make a copy of the back shape in each place where you have marked it and transfer the copy of all these shapes to the cardboard. Wright down the same numbers on each horizontal cardboard profile.

4. Make profiles of the side shape of the back shoe last part.

Mark 2 points on the bottom surface and top surface of the shoe last on the distance of 1 cm from the central line on the outer and inner sides of the last.

Place the gauge contour to each top and bottom mark in the way where the wall (pins) of the gauge touches the first mark on the top and the first mark on the bottom surface on each side of the shoe last. Do the same thing with second points on the top and bottom surfaces on each side of the shoe last to have at least 4 side profiles of the back part.

5. Shorten the back part of the last

Sand with the rasp the back part on needed distance depends on how much you want to shorten the shoe last. Sand always in a straight direction (90 degrees angle to the back surface) and check yourself each time with the vertical profile. Do the same thing with both halves of the shoe last.

6. Shape the side curves of the shoe last back working with control horizontal and side profiles.

Sand with the rasp the side parts of the shoe last until they will match each contour of the horizontal profile. Control the side shape with the side profiles.

7. Fix the shoe last shape if needed

If you sanded too much in someplace and you get the gap between some of the profiles and the shoe last shape you can fix it by refilling with epoxy clay. Apply it where you need and control it with the needed profile

This is a short explanation of the process of the shoe last shortening working with control profiles. The process is a little bit complicated and involves a lot of patience and time but it will give great results in the end.

To learn more about epoxy clay continue reading this post. Also, to sand easier the shoe last you can use some clips or bench vise to hold the shoe last.

Now, it is a little bit hard to explain every tiny step of the shoe last shortening process, so I made a tutorial for you. There are many intricate details in shoemaking that might not immediately come to mind. If you're curious about the entire shoe crafting process, I encourage you to explore this page: "How to Make Shoes".

Watch the tutorial on how to shorten your shoe last, leave your comments below, and continue reading for another insightful shoemaking tutorial on how to alter the toe shape of the shoe last.

Change your shoe last shape with epoxy clay

You can work with epoxy clay when you want to make;

rounded shape

square shape

an asymmetrical shape

You can find epoxy in any hardware store . Here is an example : https://www.amazon.com/Star-Brite-Epoxy-Putty-Stick/dp/B07FYZKGSG

It is very easy to work with the epoxy clay.

When you mix it, it becomes very soft, so you can create any shape on your shoe lasts.

When it dries it becomes hard and solid, so you can shape it even more to get the desirable form.

What is important to know here is, you must be very careful during lasting, to not break the epoxy.

In this shoemaking step (lasting) we must hit on the last here and there, so be gentle.

Another great thing about working with epoxy is, that you can always take it off, if you don’t like the shape anymore or if you want to create a new toe shape.

Change your shoe last shape with vegetable tanned leather

If you want to make a pointed toe shape on your last, use another shoemaking approach

Work with vegetable tanned leather.

The pointed toe shape made from leather will not break during lasting process.

It is a little bit harder to work with leather then working with epoxy clay, but it is safer.

Meaning that the shape that you will create on your shoe last will last longer and won’t break.

Make sure to watch this shoemaking video I made, going through all these shoemaking techniques.

Some of you already making shoes or just getting started, please take a minute and let me know (in the comment), which of the techniques you would prefer to use in your work? and don't forget to visit this page:"How to make shoes" for more insights about making shoes.

I reckon, after reading what you have stated here, that I will have to use cement and leather to widen my last, rather then plastic putty. Thank you!

I appreciate for the work you have put on an effort to create this helpful documents

I would prefer changing the shape of the last using the vegetable leather since my feet are wide and most shoes are uncomfortable for me at the toes due to the shoes been too narrow

Yes, that is something we do in my bespoke courses