The History and Tradition of Cowboy Boot Making

A true American icon with a rich history and culture, cowboy boots are often referred to as "western boots" or "rodeo boots." When cowboys were herding cattle over the Great Plains in the middle of the 19th century, the history of cowboy boots officially began. These tough men needed boots that could survive the rough terrain of the path while also being comfortable and long-lasting.

Cobblers created the first pair of cowboy boots using the same techniques they had been using for years to create work boots for farmers and tradespeople. The boots were handcrafted with thick leather and solid stitching. They had pointed toes to make it simple to enter and exit the saddle and high heels to help maintain the foot in the stirrup.

The Evolution of the Western Style of Boots

The craft of "bootmaking" and "shoemaking" flourished alongside the popularity of cowboy boots. Bootmakers began to experiment with diverse forms and shoe patterns, and new procedures were devised to make the boots more comfortable and durable. The "shoe last" became a crucial component in cowboy boot production since it allowed bootmakers to provide a unique fit for each client.

Note: shoe last is one of the most impotant tool we need to have to make shoes, so if you want to learn more about it, check this post: “Shoe Last [Definitive Guide in 2022]”

Cowboy boots are still handcrafted today utilizing many of the same methods that were created more than a century ago.

The top bootmakers still create boots using the age-old "shoemaking" technique. In this method, the leather is cut, sewn, and shaped around the "shoe last", a wooden form that gives the boot its shape. This method guarantees the durability and comfort of the footwear. These boot manufacturers include Lucchese, Justin Boots, Tony Lama, Old Gringo, and Durango Boot, to name a few.

Some useful websites related to cowboy boot making:

The Artistry of Cowboy Boot Making

Over time, as bootmakers experimented with various hues, designs, and decorations, the western boot style has changed, the materials used in making cowboy boots are very diverse.

Note: if you are beginner in shoemaking and want more about leather types we use for making shoes, I advise to check this post “Best Leather Types For-Beginners in Shoemaking”

The traditional pointed-toe shape associated with cowboy boots changed and now there are a lot of different styles of shoe lasts for cowboy boots. They are produced in mass production by different shoe factories and by individual bespoke shoemakers. The difference between factory-made cowboy boots and cowboy boots made by shoemakers is not only in the exclusive design with a lot of details but also in the process of making itself. Shoemaker makes cowboy boots using a traditional approach of making cowboy boots with handstitched soles, with leather counters (inner shoe parts), working with customized according to the feet of the client shoe lasts.

make your own sneakersLearn To Make Any Sneakers Design20 LessonsCourse Length: 25 HoursWatch & downloadIn this course, you will learn how to make sneakers by

English welted Brogue Oxford Shoe CourseThis unique course will teach you how to create handmade welted shoes from taking foot measurements to The finished pair

Note: If you want to know more about these inner shoe parts- counters, make sure to check this post “How to Make Shoe Toe Puffs? Shoemaking Training”

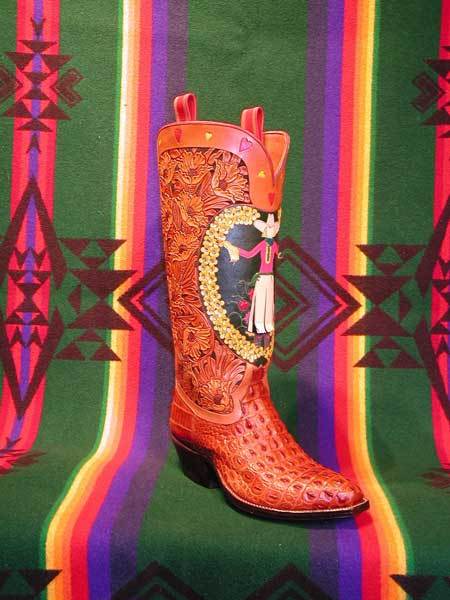

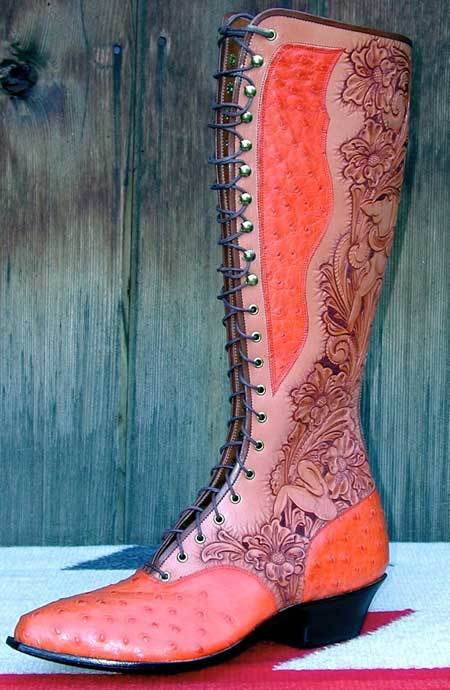

I sincerely can say that many cowboy boots made by bespoke shoemakers are real pieces of art.

The artistry of their leather decoration made on the upper of the boots, where they cut such small leather details, with many other tiny parts together is beyond any generic stamp made in manufactured cowboy boots.

See, for example, this amazingly crafted cowboy boots by William Shanor with whom I made an interview few years ago that you can find here below (continue ridding).

Although there is a big diversity in cowboy boots, ranchers, and rodeo competitors continue to wear the original design of cowboy boots because they are still fashionable.

I can vouch for the craftsmanship and elegance of cowboy boot creation as a professional shoemaker with over 20 years of expertise. It is a craft that demands dexterity, endurance, and a thorough comprehension of the tools and methods employed.

The pattern making and making process itself is different from making classic ankle boots or high boots and if you want to learn how to make these classic boot type, you can check this course of mine “High Women Boot Course” , also if you want to learn how to make ankle chelsy boots, you can check this course too “Ankle Boot Course”.

The end product, a pair of cowboy boots that will be cherished and worn for many years, never fails to impress me.

Finally, cowboy boots are a national symbol of the United States with a long history and heritage.

Master shoemaker and bootmaker William Shanor shares his proffasional wisdom

Sveta has created a comprehensive, highly skilled, amazing body of work, that is both accessible and affordable for the newcomer as well as the experienced. I have admired what she has created for many years….no one comes close to what she can provide.

William Shanor

MASTER SHOEMAKER, BONNEY AND WILLS SCHOOL OF SHOEMAKING AND DESIGN

I always wanted to learn how to make cowboy boots and there is nothing better than to learn shoe-making from a pro. Although I am making shoes for years there is always something to learn and I don’t think it will ever change. I am super excited about today’s post, and I know you will be too when you’ll see all the gold and diamonds. Today I have an awesome interview with you that I did with William Shanor. William is making cowboy boots for over 30 years former teacher at Ashland Oregon shoemaking school. Starting his career as a shoe cobbler, he learned the craft of boot making and developed his own style that you can see in the pictures below.

In this interview we talk about boot making, focusing on the small details to understand how they are made. So, let’s get right to it, my interview with one of our own members here at Shoemaking Courses Online, William Shanor from Bonney&Wills shoemaking school.

Can you tell me about your background? How did you start to make shoes? And why did you choose to focus on making cowboy boots?

I wasn’t born into the shoemaking trade, but my father owned a men’s retail shoe store. I worked there starting at twelve and helped out until I went to college at nineteen. My undergraduate studies were in psychology and continued after college while I was in the Air Force, finally getting an MA. I continued my studies, adding 50 more credits, but finally realized at twenty-seven that my passion was in my hands. So, off to Miami Florida, and running the largest shoe repair in the South East. Two years of 252 customers a day and working for my Father was “crazy-making”, so off to Oregon in a VW Bus and three children……I must have really been crazy, but I truly loved working with my hands.

Finally, after rebuilding 600,000 pairs of shoes, I said. “There has to be more than this….why not learn to make Cowboy Boots?” Considering I lived in Grants Pass, Oregon, making Western-style boots was the logical path into shoemaking. That was thirty-two years ago.

One of the most noticeable details about cowboy boots it’s the decorations. Is there a traditional ornament that is usually placed on the boots or does each boot maker creates his own?

Western boot designs are driven by tradition, region, and type of Cowboy. For example, there are Texas Cowboys, Great Basin Cowboys, Vaqueros, Vegas Glitter Cowboys, and on and on. However, three design elements can identify the specific maker of each pair of boots. The tongue shape at the top of the instep is number one. Lucchese, Ledy, Blutcher, Griffith, Paul Bond, Ray Jones, and Lisa Sorrell, all are easily recognizable. Next, the toe stitching (medallion) and the cording pattern at the ball and toe are true signature elements. Also, many makers have a toe style that is associated with their boots, for example, the famous Lucchese L toe.

The pattern of cowboy boots is pretty simple and the most difficult work that needs to be done is with the decorative elements. It’s very hard to make the pattern of those elements ( sometimes there are 20-30 elements on the boot), and I guess it’s even harder to mark and assemble it accurately on the upper.

Is there a technique that you can share on how you should transfer this kind of pattern to the upper?

Of course, stitch patterns are applied to tops using paper patterns that usually have been perforated by a sewing machine without thread in the machine. As most patterns are bi-laterally symmetrical you can just fold the front and back panels and get the entire panel perforated by just sewing one side and then unfolding the panel. Rubber cement is then applied to the grain size of the shaft leather, and the stitch pattern is pounced on with talc. Some bookmakers make the back top panel bigger than the front top panel, so this creates a “balanced Look” problem. However, the wider back panel boot fits better and has a more elegant look.

With an overlay, underlay, cording, stitching, and multiple layers of kid and kangaroo, boots sometimes can get complicated. The organization, thin elements, and planning make it all come together. Too much cementing stiffens things up so the best technique is to use double-sided tape in placing design elements before sewing…….a million uses and techniques…and no cement mess.

I noticed that cowboy boot last has shape and construction that is different from ordinary boot last. It has curved and extended insteps and the heel construction is like a court shoe last. Usually, in the boot last, the heel line reaches the ankle and only then takes the shape of the foot. Why there is a difference between cowboy boots last and ordinary last?

The extended instep is the result of the narrowing of the shank area. Cowboy boots were originally designed for riding with the narrower shank being preferred. The required instep measurement has to come from somewhere, and the “apparent” raised instep is the answer. Because Cowboy boots use a thick oak-tanned counter, not a slip-in counter, they are very stiff at the counter. If the counter sides were pinched like a traditional shoe, it would be even harder, maybe impossible, to get on. Cowboy boot lasts are therefore wider at the top of the last heel.

What are the tools used only by cowboy boot makers?

In my experience, there are not any tools that are exclusive to Western boots. Two tools that are used more in Cowboy bookmaking are Crimp Boards (blocker boards) and crimp screws used to pre-stretch the vamps and tongue area. Also, many makers use special shank-lasting pincers. (shanklasters). There is no mystique associated with Cowboy boot construction.

Why are the shoe counters sewn during the assembling of cowboy boots and not during lasting, as we do in ordinary shoes?

As noted, Cowboy boots use a thick oak-tanned counter which is not slipped in between a liner and the quarters or counter piece. The counter is stitched to the back panel and then the counter piece is added and stitched completely through the back panel and the counter….a very strong construction. Many times a heel slide is added to the back panel adding one more layer to stitch through.

If I am not mistaken the upper and lining of cowboy boots are cemented together. It’s not done in ordinary boots, so what is the reason you do it in cowboy boots?

The top outer and lining are rubber cemented together for strength, ease of topstitching, and to facilitate side seaming. Cowboy boots are made in two pieces, front and back, inside out, and then sewn together on the panel edges with a welt in between. If the liners were not cemented to the tops, side seaming would be almost impossible.

How long it takes to make cowboy boots? and do you teach how to make cowboy boots at your shoemaking school?

Construction time, as a rule of thumb, is about 40 hours but can range from 12 hours(the fastest I’ve heard) to hundreds of hours. I made a pair that took 155 hours, hands-on. I stopped teaching Cowboy boots, but have decided to begin again. The course I plan will last three weeks and will be very unique. Two weeks will be dedicated to creating a traditional boot. In the final week I will teach four other Cowboy boot construction methods: packer, one-piece top, two-piece Wellington, and triads. Instructions and patterns will be provided. I feel once the basic boot is mastered, the final week’s information will benefit the student for years to come.

It was hard for me to find the right place to learn shoemaking many years ago, and that is what drove me to share my knowledge and teach how to make shoes. Why and how did you start your shoemaking school?

About 15 years ago I started teaching Renaissance moccasin courses. But, I finally just decided to teach the “whole thing”. I searched a long time for a good webmaster, put up a website, and “BOOM” we were off to the races….totally amazing! Frank Jones was my mentor and motivator, not to mention giving me the domain name: shoemaking.com. Such a dear friend and a fine human being.

Are your shoemaking courses suited for beginners and what shoemaking courses do you teach at your school?

Yes, our courses are geared toward beginners. And, we expect them to work very hard and focus, because we cover: measuring, last selection and modification, pattern making, insole construction, cutting, closing, lasting, etc. They do every step to the maximum of their ability. I teach fashion pumps…beginner and advanced, men’s dress shoes, hiking boots, fashion boots, Renaissance moccasins, stitch-down shoes, and

Western boots. I am developing an advanced, totally traditional, course for men’s style shoes. Frank Jones thinks we have the best teaching facility in the US, and we are constantly trying to improve it.

I hope you found this interview useful, I know I made a full notebook of notes. As someone who loves Cowboy boots, I will certainly try to make myself available to visit William School in Oregon to learn from the best. I know some of the members here learned with William and you are more than welcome to share your experience here.

I want to say a big thank you to William Shanor for doing this interview and sharing his knowledge with us. For more details about Bonney & Wills shoemaking school, you can contact him directly :

[email protected]

Very informative, thank you! Where can I buy the Crimp Board?

I I make cowboy boots on cd. Juarez Chih. Mx with excellent quality and have learned empirically most of the workers in the factories of boots in Paso Tx are Mexicans from Cd Juarez as both Luccesse as Tomy Lama, if something can bring to your blog I am at your orders greetings …

Sure we would love to see your boots.Please share your knowledge.

Its always really cool to get insight into my fathers mind when it comes to his creativity. I think I may be his biggest fan.

That is great! Following your father’s footsteps in shoemaking?

I took my 2 courses from Bill and have to say that I wish I had met him 20 years sooner. He is an amazing talent and a very patient teacher. As soon as funds allow I plan to return to his school and take another of his courses. His teaching is very intense and requires a lot of focus as you cram a lot into the time allotted. The one thing that sets his school apart from all the others I have checked into is that there is nothing “cookie cutter” in the way he teaches. Each student designs a unique pair of footwear in the style being taught and the lessons are adapted to fit accordingly. Every student in a given class will learn all the variations of technique needed for each pair of shoes made during their particular class. The basic techniques are always the same but the differences between a single cut Oxford and a full brogue are substantial. And the similarities between Oxford and Derby can be surprising while the differences are surprisingly difficult. We had these as well as Monk style shoes when I took my course on Men’s Dress Shoes from him. The lessons apply equally to women’s styles as well. He’s now hosting an annual footwear symposium in Ashland every spring. Definitely worth checking out.

Yeap, William is a great shoemaker and I am very proud to have him as a member in my courses.

That a great job, not just shoe making but art work wow you are amazing. How I wish I can give a trial. I am interested in making shoes, though I love the boot, and have been learning from a local shoe maker in my community. I like you to be a guide. I have also, tried making a Chelsea boot, and I found that I really need a crimping board, but can't afford one now. but if I have the dimensions I can produce one locally. Please can you assist me with a crimping board dimensions? Thank you

I made my boards from ash. The dimensions for my boards 5.5 inches across the top x 10 inches from top to bottom and 15 inches from back to front. Start the curve to the toe

about 3 inches from the top.